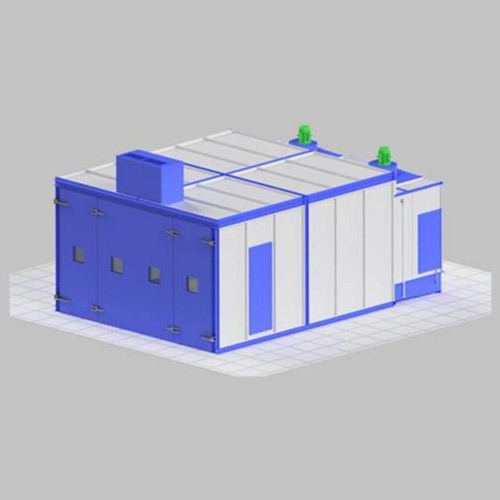

Blast Room Systems

Price 2700000 INR/ Piece

MOQ : 1 , , Piece

Blast Room Systems Specification

- Lifting Speed

- 6 m/min

- Motor Power

- 7.5 HP

- Surface

- Coated

- Lifting Height

- 6 m

- Product Type

- Blast Room Systems

- General Use

- Abrasive blasting cleaning operations

- Material

- Heavy Duty Steel

- Type

- Fully Enclosed

- Capacity

- 500 kg/Batch

- Weight (kg)

- 2500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Panel Controlled

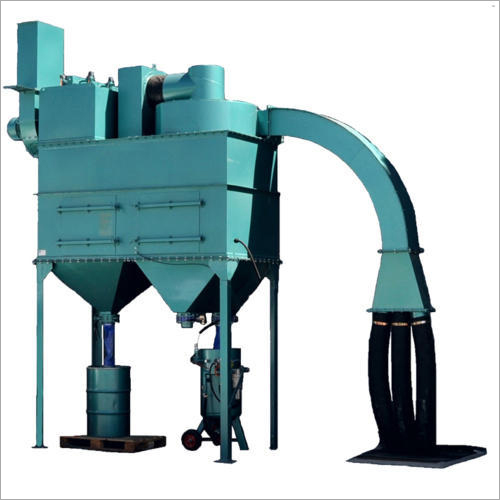

- Cooling System

- Dust Collector with Ventilation

- Method

- Pressure/Suction Blast

- Voltage

- 415V, 3 Phase

- Dimension (L*W*H)

- 6000 mm x 4000 mm x 4000 mm

- Feature

- High Efficiency, Durable, Robust Construction

- Color

- Industrial Blue & Grey

- Door Type

- Manual Swing Doors

- Abrasive Recovery System

- Mechanical & Pneumatic

- Noise Level

- Below 85 dB

- Blast Media Compatible

- Grit, Shot, Sand

- Dust Emission

- Below permissible limits as per standards

- Air Requirement

- 8-10 bar

- Control Panel Type

- PLC

- Blast Nozzle Quantity

- 2

- Operator Safety Features

- Interlocked Access Doors, Safety Gear support

- Lighting

- LED, Dust Proof

- Floor Type

- Wear-Resistant Mesh Floor

Blast Room Systems Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Delivery Time

- 12-16 Week

About Blast Room Systems

Unlock majestic efficiency with our sizzling Blast Room Systems, now on sale for an unrivaled bargain! This ravishing, fully enclosed unit features two robust blast nozzles, both mechanical and pneumatic abrasive recovery systems, and energy-saving LED, dust-proof lighting. Engineered from heavy-duty steel, the system ensures operator safety with interlocked doors, support for safety gear, and noise levels below 85 dB. Equipped with a wear-resistant mesh floor, powerful 7.5 HP motor, and a high-lifting speed, it's designed for exceptional durability and robust cleaning performance in abrasive blasting operations.

Unmatched Features & Versatile Commercial Use

Our Blast Room Systems are packed with additional features, including a wear-resistant mesh floor, panel-controlled PLC operation, and robust safety provisions. Made for abrasive cleaning using grit, shot, or sand, this powerful system is ideal for industries like automotive, foundries, and fabrication. Easy to operate: simply load batches, select your blast settings, and monitor via the clear PLC interface. Experience seamless, high-efficiency cleaning for large quantities up to 500 kg per batch.

Streamlined Payment Terms & Hassle-free Delivery

We offer convenient payment terms, ensuring a smooth purchasing experience for every client. Sample policies are designed to accommodate a variety of commercial requirements, with samples available upon request. Our efficient dispatching system guarantees timely transportation and drop-off at your chosen location, making sure your Blast Room System arrives on schedule and in perfect condition. Trust our streamlined process for a stress-free journey from order placement to delivery.

Unmatched Features & Versatile Commercial Use

Our Blast Room Systems are packed with additional features, including a wear-resistant mesh floor, panel-controlled PLC operation, and robust safety provisions. Made for abrasive cleaning using grit, shot, or sand, this powerful system is ideal for industries like automotive, foundries, and fabrication. Easy to operate: simply load batches, select your blast settings, and monitor via the clear PLC interface. Experience seamless, high-efficiency cleaning for large quantities up to 500 kg per batch.

Streamlined Payment Terms & Hassle-free Delivery

We offer convenient payment terms, ensuring a smooth purchasing experience for every client. Sample policies are designed to accommodate a variety of commercial requirements, with samples available upon request. Our efficient dispatching system guarantees timely transportation and drop-off at your chosen location, making sure your Blast Room System arrives on schedule and in perfect condition. Trust our streamlined process for a stress-free journey from order placement to delivery.

FAQ's of Blast Room Systems:

Q: How does the abrasive recovery system work in this Blast Room System?

A: The system features both mechanical and pneumatic abrasive recovery, ensuring efficient collection and recycling of blast media for sustainable, cost-effective operation.Q: What is the recommended usage for this Blast Room System?

A: It is ideal for abrasive blasting cleaning operations in industries such as automotive, foundries, and metal fabrication, accommodating batches up to 500 kg.Q: When should maintenance be performed on the Blast Room System?

A: Regular maintenance is advised after thorough inspection cycles, especially for wear-resistant mesh flooring and filters, to guarantee optimal performance and longevity.Q: Where can the Blast Room System be installed?

A: Due to its fully enclosed and robust design, it can be set up in industrial settings with standard 3-phase, 415V power supply and sufficient air pressure (8-10 bar).Q: What safety features protect operators during use?

A: Key safety elements include interlocked access doors, provisions for safety gear, and noise levels kept below 85 dB to protect hearing and ensure operator security.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS